LKQ Remanufactured Car Engines Guide - Quality and Cost Information Guide

When facing major engine problems, vehicle owners often consider replacement options. LKQ remanufactured car engines represent a cost-effective alternative to new factory engines, offering reliability at a fraction of the price. These engines undergo rigorous inspection, restoration, and testing processes to meet or exceed original equipment specifications, making them a practical choice for many drivers seeking quality engine replacements.

When facing engine failure or significant mechanical issues, vehicle owners often weigh their options between purchasing a new engine, a used engine, or a remanufactured one. Remanufactured engines have gained popularity as a middle-ground solution that balances cost savings with dependable performance. LKQ Corporation has established itself as a significant player in this market, offering remanufactured engines that meet specific industry standards.

Understanding LKQ Remanufactured Car Engines

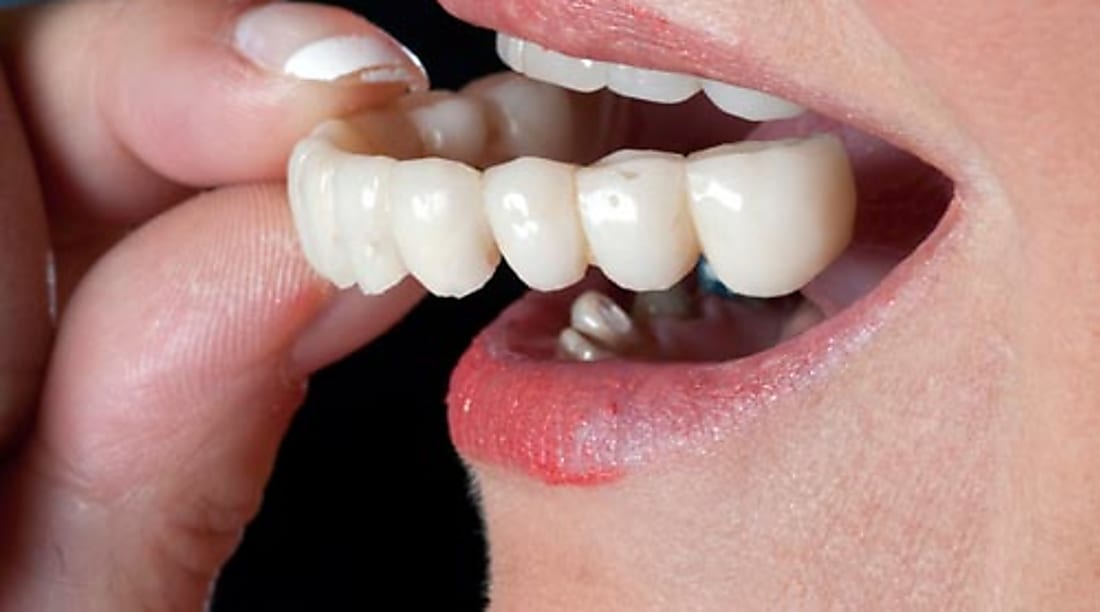

Remanufactured engines differ fundamentally from used engines. While a used engine is simply removed from another vehicle and resold, a remanufactured engine undergoes a comprehensive restoration process. LKQ specializes in taking worn or damaged engines and rebuilding them to meet or exceed original equipment manufacturer specifications. This process involves disassembly, cleaning, inspection, replacement of worn components, reassembly, and testing. The result is an engine that functions like new but comes at a fraction of the cost. LKQ sources engines from salvage yards, auctions, and other suppliers, then processes them through their remanufacturing facilities across the country. These engines are designed to provide reliable performance for thousands of miles when properly installed and maintained.

The Remanufacturing Process Explained

The remanufacturing process is what distinguishes these engines from simple rebuilds or used alternatives. LKQ follows a systematic approach that begins with core acquisition and inspection. Each engine core is evaluated to determine its suitability for remanufacturing. Engines that pass initial inspection are completely disassembled, and every component is cleaned and examined. Worn parts such as pistons, bearings, gaskets, seals, and timing components are replaced with new or remanufactured parts that meet original specifications. Critical components like crankshafts and cylinder heads are machined to restore proper dimensions and surface finishes. The engine block may be bored and honed to ensure proper cylinder wall condition. After reassembly, each engine undergoes testing to verify proper operation, compression, oil pressure, and absence of leaks. This thorough process ensures that remanufactured engines deliver performance comparable to new engines while utilizing the existing block and major castings.

Quality Standards and Warranties for LKQ Engines

Quality assurance is central to the remanufacturing industry, and LKQ implements various standards to maintain consistency. Many LKQ remanufactured engines are built to meet standards established by organizations such as the Automotive Engine Rebuilders Association. These standards outline specific procedures for machining tolerances, component replacement, and testing protocols. LKQ typically provides warranties on their remanufactured engines, though coverage terms vary depending on the specific product line and distributor. Standard warranties often range from 12 months to 36 months or specific mileage limits, whichever comes first. Some premium remanufactured engines may include longer warranty periods. Warranty coverage generally includes parts and labor for defects in materials or workmanship but may exclude damage caused by improper installation, lack of maintenance, or external factors. Buyers should carefully review warranty documentation and understand any registration or installation requirements that may affect coverage validity.

Benefits of Choosing Remanufactured Engines

Selecting a remanufactured engine offers several advantages for vehicle owners. The most obvious benefit is cost savings compared to purchasing a new engine from a dealership. Remanufactured engines typically cost 30 to 50 percent less than new engines while providing similar reliability and longevity. Environmental benefits also factor into the decision, as remanufacturing reduces waste by reusing existing engine blocks and major components rather than manufacturing entirely new units. This process conserves raw materials and energy. Availability is another consideration, particularly for older or discontinued vehicle models where new engines may be difficult or impossible to obtain. LKQ maintains an extensive inventory covering a wide range of makes and models. Installation is generally straightforward since remanufactured engines are designed as direct replacements for original engines, fitting existing mounts, connections, and accessories. Performance and reliability, when properly installed, should match or exceed the original engine’s capabilities, especially if the original engine had accumulated significant wear over many years of use.

Cost and Pricing Factors for LKQ Remanufactured Engines

Pricing for remanufactured engines varies significantly based on multiple factors. Engine size, complexity, and vehicle application all influence cost. A four-cylinder engine for a compact car will generally cost less than a V8 engine for a truck or performance vehicle. The specific LKQ product line also affects pricing, with standard remanufactured engines priced lower than premium or performance variants. Geographic location and local market conditions can create price variations across different regions. Most remanufactured engine purchases involve a core charge, which is a deposit refunded when the old engine is returned to the supplier. This incentivizes recycling and provides cores for future remanufacturing.

| Engine Type | Typical Price Range | Core Charge | Warranty Period |

|---|---|---|---|

| 4-Cylinder Standard | $1,800 - $3,500 | $300 - $500 | 12-36 months |

| V6 Standard | $2,500 - $4,500 | $400 - $600 | 12-36 months |

| V8 Standard | $3,200 - $6,000 | $500 - $800 | 12-36 months |

| Diesel Engine | $4,500 - $9,000 | $800 - $1,500 | 12-24 months |

| Performance/Premium | $4,000 - $8,000 | $500 - $1,000 | 24-36 months |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Additional costs beyond the engine itself include shipping or delivery fees, which can range from $150 to $400 depending on engine size and distance. Professional installation labor typically adds $500 to $1,500 or more, depending on vehicle complexity and local labor rates. Additional parts such as gaskets, fluids, filters, belts, and hoses needed for installation may add $200 to $500 to the total project cost. Some vehicles may require additional components like motor mounts, sensors, or wiring harnesses, further increasing expenses.

When comparing remanufactured engines from different suppliers, consider not just the initial price but also warranty coverage, core charge policies, return procedures, and the supplier’s reputation for quality and customer service. Obtaining quotes from multiple sources and verifying what is included in the price helps ensure informed decision-making. Working with experienced mechanics familiar with remanufactured engine installations can prevent costly mistakes and ensure proper setup for long-term reliability.

Remanufactured engines from suppliers like LKQ represent a viable solution for vehicle owners facing major engine repairs. By understanding the remanufacturing process, quality standards, benefits, and cost factors, consumers can make informed choices that balance budget constraints with performance expectations and long-term vehicle needs.