Industrial Machines: Backbone of Modern Manufacturing

Manufacturing has evolved dramatically over the past century, transforming from labor-intensive processes to sophisticated automated systems. At the heart of this transformation lie industrial machines - complex mechanical systems that have revolutionized how products are designed, produced, and delivered to consumers worldwide.

Manufacturing facilities worldwide depend on advanced equipment to maintain competitive advantages in today’s fast-paced market. These complex systems represent significant technological achievements that continue to evolve, incorporating advanced automation, artificial intelligence, and precision engineering to meet growing production demands.

How Manufacturing Equipment Drives Efficiency in Modern Production

Efficiency improvements through manufacturing machinery stem from their ability to perform repetitive tasks with consistent accuracy while operating at speeds impossible for manual labor. Computer-controlled systems eliminate human error in critical processes, ensuring product quality remains uniform across large production runs. Advanced sensors and monitoring systems provide real-time feedback, allowing operators to adjust parameters instantly when deviations occur.

Automated material handling systems reduce bottlenecks by coordinating the flow of components through production lines. These systems minimize downtime between operations and optimize resource allocation, resulting in higher throughput rates. Integration with enterprise resource planning software enables predictive maintenance scheduling, preventing unexpected breakdowns that could halt entire production lines.

The Role of Manufacturing Equipment in Shaping the Future of Production

Emerging technologies are transforming manufacturing machinery into intelligent production partners. Machine learning algorithms analyze production data to identify optimization opportunities that human operators might overlook. Internet of Things connectivity allows machines to communicate with each other, creating synchronized production environments where equipment adjusts automatically to changing conditions.

Additive manufacturing technologies are expanding beyond prototyping into full-scale production applications. These systems enable on-demand manufacturing of complex geometries that traditional machining cannot achieve. Digital twin technology creates virtual replicas of physical machines, allowing engineers to test modifications and predict performance before implementing changes on actual equipment.

How Advanced Manufacturing Equipment Improves Production Processes

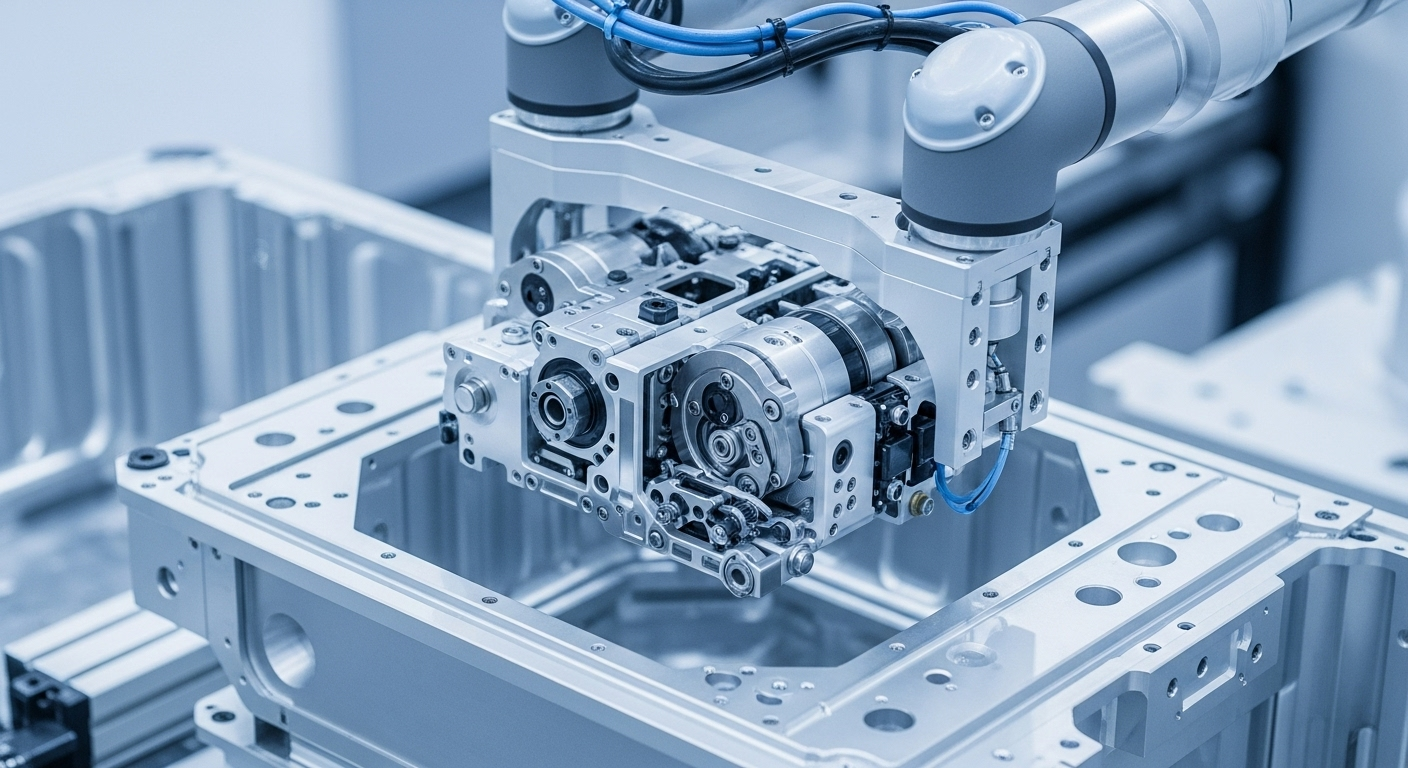

Modern manufacturing equipment incorporates multiple technologies to enhance process capabilities. Vision systems inspect products during manufacturing, identifying defects before they reach quality control stations. Robotic arms equipped with force sensors can handle delicate materials while maintaining precise positioning accuracy measured in micrometers.

Multi-axis machining centers perform complex operations in single setups, reducing handling time and improving dimensional accuracy. Laser processing systems offer non-contact manufacturing methods that eliminate tool wear while achieving superior surface finishes. These capabilities enable manufacturers to produce components with tighter tolerances and more complex features than previously possible.

Why Manufacturing Equipment Is Essential for Today’s Production Success

Competitive pressures require manufacturers to deliver higher quality products at lower costs while meeting shorter delivery schedules. Manufacturing equipment provides the scalability needed to respond quickly to market demands without compromising quality standards. Automated systems can operate continuously with minimal supervision, maximizing facility utilization rates.

Regulatory compliance in industries such as aerospace and medical devices requires documented process control that manual operations cannot reliably provide. Manufacturing equipment generates detailed production records automatically, supporting traceability requirements and quality certifications. This documentation capability becomes increasingly important as supply chain transparency demands grow.

How Manufacturing Equipment Enhances Productivity and Reduces Costs

Productivity gains from manufacturing machinery compound over time through reduced labor requirements and increased output rates. Single machines can often replace multiple manual workstations while producing higher quality results. Energy-efficient designs reduce operational costs while meeting environmental sustainability goals.

| Equipment Category | Typical Applications | Cost Range (CAD) |

|---|---|---|

| CNC Machining Centers | Precision metal cutting, milling | $150,000 - $2,000,000 |

| Robotic Systems | Assembly, welding, painting | $50,000 - $500,000 |

| Injection Molding Equipment | Plastic component production | $100,000 - $1,500,000 |

| Automated Packaging Systems | Product wrapping, labeling | $75,000 - $800,000 |

| Quality Inspection Equipment | Dimensional measurement, defect detection | $25,000 - $400,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Long-term cost benefits extend beyond direct labor savings to include reduced waste, improved energy efficiency, and lower maintenance requirements compared to older equipment. Return on investment calculations must consider these factors alongside productivity improvements to accurately assess the financial impact of manufacturing equipment investments.

The strategic implementation of manufacturing equipment requires careful planning to maximize their potential benefits. Successful integration depends on proper training, maintenance programs, and ongoing optimization efforts that ensure equipment operates at peak efficiency throughout its operational life.