How 3D Printers Work and What They Can Create

3D printers are machines that can make real objects from digital designs. They work by building shapes layer by layer. People use them to create models, toys, tools, and even art. Learning about 3D printers helps you understand how ideas can turn into things you can touch.

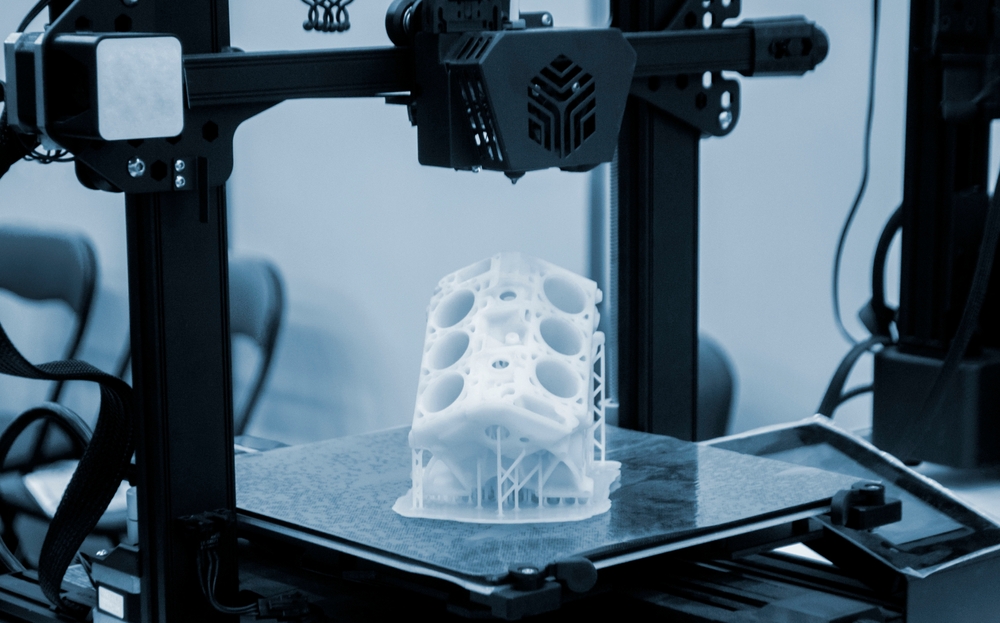

Modern manufacturing has been transformed by additive manufacturing technology that builds objects from the ground up. Unlike traditional subtractive methods that remove material, this process adds material layer by layer to create three-dimensional objects from digital files. The technology has evolved from industrial prototyping to accessible desktop solutions that serve diverse applications across multiple industries.

What is 3D Printing Technology?

3D printing, also known as additive manufacturing, is a process that creates physical objects from digital three-dimensional models. The technology reads computer-aided design (CAD) files and translates them into instructions for building objects layer by layer. Various materials can be used, including plastics, metals, ceramics, resins, and even biological materials. The process begins with a digital model that gets sliced into thousands of horizontal cross-sections, with each layer being precisely deposited or cured to form the final product.

How Do 3D Printers Actually Work?

The fundamental process involves several key steps that remain consistent across different printer types. First, a digital model is created using CAD software or obtained from online repositories. Slicing software then converts this model into layers and generates specific instructions for the printer. The printer follows these instructions to deposit, cure, or bind material layer by layer. Each layer bonds with the previous one, gradually building the complete object from bottom to top. The entire process is automated, requiring minimal human intervention once printing begins.

Types of 3D Printer Models

Several distinct technologies power different printer models, each with unique advantages. Fused Deposition Modeling (FDM) printers heat plastic filaments and extrude them through a nozzle, making them popular for beginners due to their affordability and ease of use. Stereolithography (SLA) printers use ultraviolet light to cure liquid resin, producing highly detailed objects with smooth surfaces. Selective Laser Sintering (SLS) employs lasers to fuse powdered materials, enabling complex geometries without support structures. Industrial-grade printers may use metal powders, concrete, or specialized materials for specific applications.

Common Applications of Digital Fabrication

Digital fabrication serves numerous industries and applications, from rapid prototyping to end-use production. In healthcare, practitioners create custom prosthetics, dental implants, and surgical guides tailored to individual patients. Aerospace and automotive industries use the technology for lightweight components and complex internal structures impossible to achieve through traditional manufacturing. Architecture firms produce detailed scale models and construction components, while educators use printers to create tangible learning aids. Consumer applications include custom jewelry, replacement parts, toys, and artistic creations.

Pricing and 3D Printer Options

The cost of 3D printing varies significantly based on printer type, materials, and intended applications. Entry-level FDM printers suitable for hobbyists and educational use typically range from $200 to $800, offering basic functionality for simple projects. Mid-range printers with enhanced features and larger build volumes cost between $800 and $3,000, appealing to small businesses and serious enthusiasts. Professional-grade SLA and SLS printers range from $3,000 to $15,000, providing superior quality and material options for commercial applications.

| Printer Category | Price Range | Best For | Key Features |

|---|---|---|---|

| Entry-Level FDM | $200-$800 | Hobbyists, Education | Basic materials, small build volume |

| Mid-Range FDM | $800-$3,000 | Small business, Prototyping | Larger builds, multiple materials |

| Professional SLA | $3,000-$8,000 | High detail work, Dental/Jewelry | Superior surface finish, precision |

| Industrial SLS | $10,000-$50,000+ | Production, Complex geometries | No supports needed, strong parts |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Material costs also impact overall expenses, with basic PLA filament costing around $20-30 per kilogram, while specialized materials like carbon fiber composites or medical-grade resins can cost $100-500 per kilogram. Operating costs include electricity, maintenance, and potential failed prints, which should be factored into project budgets.

The accessibility of 3D printing continues to expand as technology advances and costs decrease. From rapid prototyping to custom manufacturing, this technology enables individuals and businesses to transform digital concepts into physical reality. Whether creating simple household items or complex industrial components, 3D printing offers unprecedented design freedom and customization possibilities that traditional manufacturing methods cannot match.