Explore the characteristics and industrial applications of laser welding machines

Laser welding technology has transformed manufacturing processes across multiple industries by offering precision, speed, and versatility. This advanced joining method uses concentrated laser beams to fuse materials with minimal heat-affected zones, making it ideal for applications requiring high-quality welds. Understanding the core characteristics and industrial applications of laser welding machines helps businesses evaluate whether this technology aligns with their production needs and quality standards.

Learn About Laser Welding Technology

Laser welding represents a significant advancement in material joining processes. This technology uses a focused beam of light to generate intense heat at specific points, melting and fusing materials together. The process works by directing a laser beam through optics that concentrate the energy onto a small area, creating temperatures high enough to melt metal almost instantly. The concentrated heat input means surrounding areas remain relatively cool, reducing distortion and maintaining the structural integrity of components.

Two primary types of laser welding exist: conduction mode and keyhole mode. Conduction mode welding uses lower power levels and creates shallow welds suitable for thin materials. Keyhole mode involves higher power that vaporizes material, creating a deep, narrow weld pool ideal for thicker sections. Modern laser welding systems commonly use fiber lasers, CO2 lasers, or solid-state lasers, each offering distinct advantages depending on the application requirements.

The Main Features of Laser Welding Machines

Laser welding machines possess several characteristics that distinguish them from traditional welding methods. Precision stands as a defining feature, with laser beams focused to spots as small as a few micrometers in diameter. This precision enables welding of intricate geometries and small components that would be impossible with conventional techniques.

Speed represents another significant advantage. Laser welding processes operate much faster than traditional arc welding, with some systems completing welds in milliseconds. This rapid processing capability translates directly into increased production throughput and reduced manufacturing costs per unit.

The minimal heat-affected zone characteristic reduces thermal distortion in welded parts. Because the laser delivers energy precisely where needed, surrounding material experiences less thermal stress. This feature proves particularly valuable when working with heat-sensitive materials or components requiring tight tolerances.

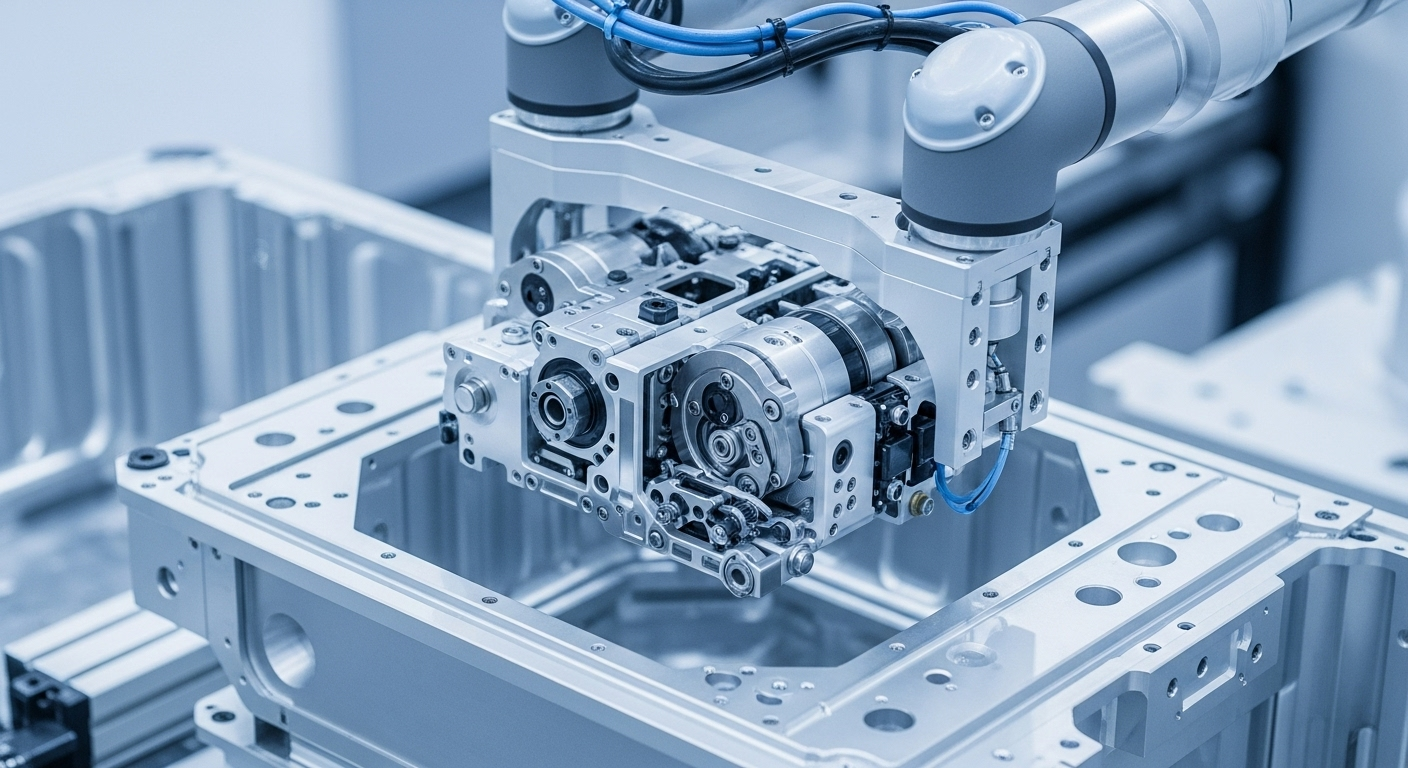

Automation compatibility makes laser welding machines ideal for modern manufacturing environments. These systems integrate seamlessly with robotic arms, computer numerical control systems, and automated production lines. The non-contact nature of the process eliminates tool wear and reduces maintenance requirements compared to resistance welding or other contact methods.

Industrial Applications of Laser Welding

The automotive industry extensively employs laser welding for body assembly, transmission components, and battery pack manufacturing. Electric vehicle production particularly benefits from laser welding capabilities, as the technology creates strong, lightweight joints in aluminum and mixed-material assemblies. Manufacturers use laser welding to join body panels, creating smooth seams that require minimal finishing work before painting.

Aerospace applications demand the precision and quality that laser welding provides. Aircraft engine components, fuel system parts, and structural elements often require welds that meet stringent quality standards. The process creates clean, strong joints in titanium, nickel alloys, and other aerospace materials while maintaining critical dimensional tolerances.

Medical device manufacturing relies heavily on laser welding for producing surgical instruments, implantable devices, and diagnostic equipment. The process creates biocompatible welds in stainless steel, titanium, and specialty alloys without introducing contaminants. The precision enables joining of extremely small components used in minimally invasive surgical tools and electronic medical devices.

Electronics and battery manufacturing sectors use laser welding for connecting thin foils, tabs, and housings. Lithium-ion battery production requires precise welding of copper and aluminum tabs to battery cells, a task laser welding performs efficiently. The minimal heat input prevents damage to sensitive battery chemistry while creating reliable electrical connections.

Jewelry and luxury goods manufacturers appreciate the precision and aesthetic quality of laser welds. The technology allows repair work on delicate pieces and creation of seamless joints in precious metals. The controlled heat input prevents damage to gemstones and enables work on pieces that traditional welding methods would destroy.

Future Trends in Laser Welding

Technological advancement continues to expand laser welding capabilities and applications. Fiber laser technology has gained significant market share due to improved efficiency, lower operating costs, and reduced maintenance requirements compared to older CO2 laser systems. The compact size and flexibility of fiber lasers enable integration into tighter production spaces and mobile welding systems.

Artificial intelligence and machine learning integration represents an emerging trend. Smart laser welding systems use sensors and algorithms to monitor weld quality in real-time, automatically adjusting parameters to maintain consistent results. These systems detect defects during production rather than through post-process inspection, reducing scrap rates and improving overall quality.

Multi-material joining capabilities continue to develop as manufacturers seek to combine different materials for optimized performance. Laser welding technology advances enable joining dissimilar metals that traditional welding struggles to fuse, such as aluminum to steel or copper to aluminum. These capabilities support lightweighting initiatives and innovative product designs.

Additive manufacturing integration shows promise for hybrid processes that combine laser metal deposition with welding. These systems can build up material and join components in single setups, reducing production steps and expanding design possibilities. The technology enables repair of high-value components and creation of complex geometries impossible through conventional manufacturing.

Green manufacturing initiatives drive development of more energy-efficient laser welding systems. Modern fiber lasers consume significantly less electricity than older technologies while delivering superior performance. The reduced energy consumption and elimination of consumables like welding wire or shielding gas align with sustainability goals many manufacturers pursue.

Conclusion

Laser welding machines offer unique characteristics that make them valuable tools across diverse industrial sectors. The combination of precision, speed, minimal thermal distortion, and automation compatibility addresses many manufacturing challenges that traditional welding methods cannot solve efficiently. As technology continues advancing, laser welding applications will likely expand into new industries and enable innovative product designs. Understanding these characteristics and applications helps manufacturers make informed decisions about implementing laser welding technology in their production processes. The ongoing development of smarter, more efficient systems ensures laser welding will remain a critical manufacturing technology for years to come.