A Complete Guide to Sandwich Panels Prices

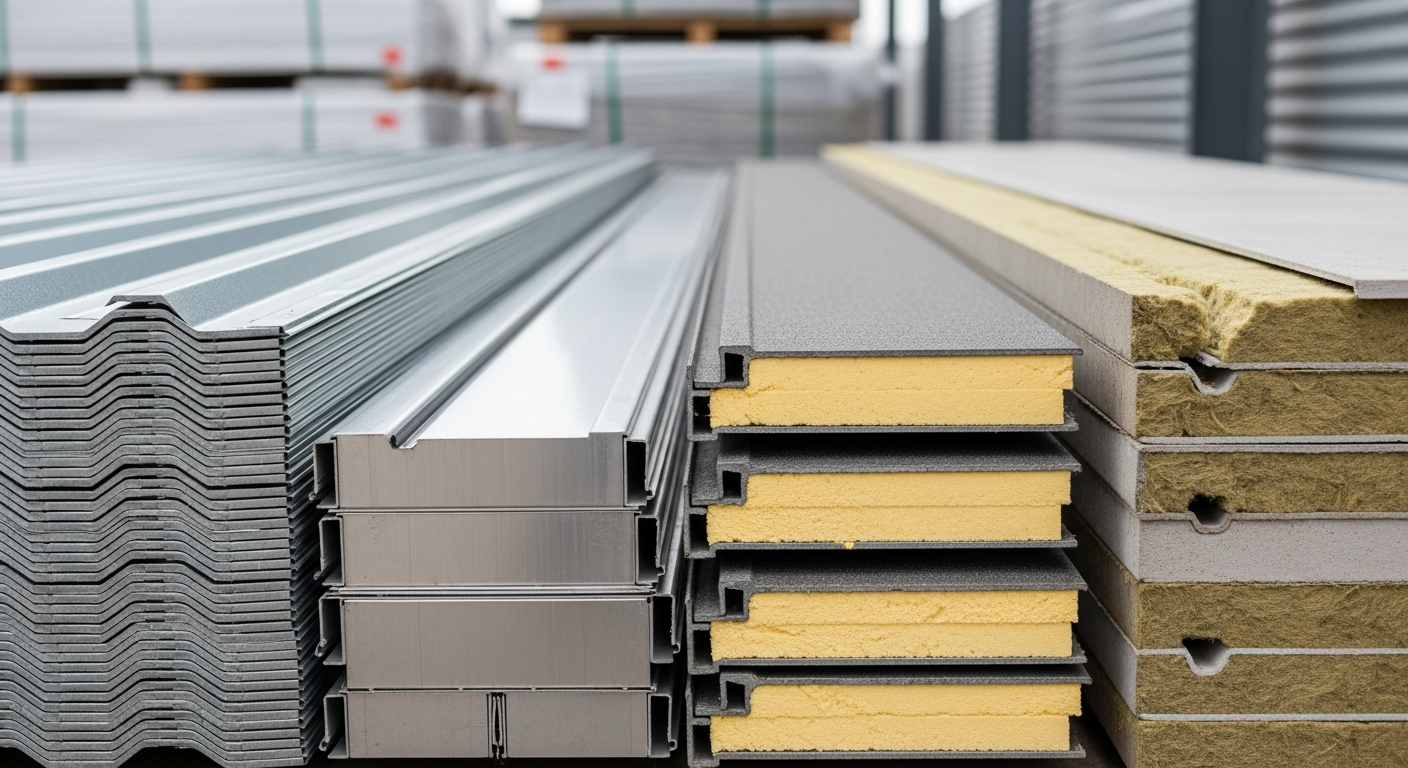

Sandwich panels have become increasingly popular in Canadian construction projects due to their excellent insulation properties and structural efficiency. These composite building materials consist of two outer layers bonded to an insulating core, offering superior thermal performance while maintaining lightweight characteristics. Understanding the pricing structure and market options available across Canada helps property owners and contractors make informed decisions for their building projects.

A Complete Guide to Sandwich Panels Prices

Sandwich panels, often called insulated metal panels, combine exterior and interior metal facings with an insulating core to deliver structure, thermal performance, and weather protection in one product. For projects across Canada, understanding how specifications translate into cost helps prevent surprises during procurement and construction. This article is a complete guide to sandwich panels prices, covering how panels are built, what drives costs, the expected price range, where to buy in your area, and tips to evaluate options with confidence.

Understanding sandwich panels construction and benefits

A sandwich panel typically uses galvanized steel or aluminum facings bonded to a rigid core such as PIR or PUR foam, expanded polystyrene, or mineral wool. Core choice influences thermal resistance, fire performance, weight, and cost. Panels are factory engineered with joint systems to control air and water, and come in profiles like flat, micro rib, or lightly profiled ribs. Benefits include faster enclosure compared to multi trade assemblies, consistent factory quality, predictable R values per inch, and reduced thermal bridging. Many systems are tested for fire resistance and air water tightness, supporting compliance with Canadian building code requirements when specified correctly for the application.

Sandwich panels price range analysis

Panel pricing reflects material, thickness, finish, quantity, and logistics. As a rule of thumb in Canada, supply only prices commonly start with EPS cores on the low end and increase for PIR PUR and mineral wool. Typical material ranges are EPS about CAD 6 to 12 per square foot, PIR PUR about CAD 9 to 18 per square foot, and mineral wool about CAD 12 to 22 per square foot, depending on thickness, gauge, and coatings. Food grade or specialty finishes, stainless facings, long lengths, or custom colours can add premiums. Installed prices, which include labour, equipment, sealants, and trims, often run about CAD 18 to 30 per square foot for simple low rise wall runs, and CAD 30 to 45 or more where there are tall elevations, many openings, or tighter tolerances such as in cold storage facilities. These figures are estimates and vary by region and market conditions.

Where to buy sandwich panels in Canada

You can source panels through manufacturers and their authorized distributors, specialty metal envelope contractors, and larger building supply dealers that handle commercial cladding. Reputable manufacturers active in Canada include Kingspan Insulated Panels, Metl Span, Norbec, and All Weather Insulated Panels. For local services, contact regional sales offices to be directed to approved installers in your area. When comparing quotes, ask for clear scope definitions that include trims, flashings, fasteners, sealants, shop drawings, delivery, and offloading. Lead times can fluctuate with plant capacity and colour selection, so verify schedules early, especially for seasonal builds or remote locations where freight planning is critical.

Tips to find the right sandwich panels

Start by defining performance priorities energy efficiency, fire performance, or hygiene for process spaces. Select a core aligned to those needs, then size thickness to meet your project s effective R value targets based on local climate zone and code. Confirm the panel joint type, air and vapour control strategy, and compatible accessories. Request samples to assess coating durability and appearance. To sharpen pricing, provide takeoffs with panel lengths, elevations, and penetrations to reduce waste. Ask for alternate options such as standard colours, common lengths, or PIR instead of mineral wool when fire ratings permit. Compare warranties, installer qualifications, and documented test data, not just unit price. Finally, obtain both supply only and installed figures to understand trade offs between direct purchasing and turnkey delivery.

A practical pricing snapshot and vendor overview can help frame budgets before detailed quotes. The ranges below are material only estimates for common insulated metal wall panels in Canada and will vary with thickness, finish, colour, quantity, and logistics. Always verify current pricing and availability with the provider or an authorized distributor.

| Product Service | Provider | Cost Estimation |

|---|---|---|

| Insulated metal wall panels PIR foam | Kingspan Insulated Panels | CAD 12–20 per sq ft material only |

| CF Series insulated wall panels PUR PIR | Metl Span | CAD 11–19 per sq ft material only |

| Insulated metal wall panels mineral wool | Norbec | CAD 14–22 per sq ft material only |

| Design Wall insulated panels PIR MW | All Weather Insulated Panels | CAD 11–20 per sq ft material only |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Conclusion Sandwich panels combine structure, insulation, and cladding into a single, factory controlled product, delivering speed and performance for Canadian projects. Costs hinge on core type, thickness, finish, complexity, and freight, with material ranges that scale from economical EPS to higher performance PIR PUR and mineral wool. By shortlisting reputable providers, specifying requirements clearly, and seeking apples to apples quotes that separate material and installation, buyers can align budget with performance and schedule while minimizing risk across design and construction.